Project Log: Friday, June 5, 2015

One of the final details not yet dealt with was new

sailcovers for both main and mizzen. To this end,

Jason, my upholstery and canvas contractor, and I agreed

to meet in the morning and mock up the booms and sails

so he could pattern the sailcovers and have them ready

in time for launching.

With the masts already set up on sawhorses, it was

pretty straightforward to attach the booms--one mast at

a time--and bend on the sails in a rough approximation

of their eventual stored state, from which Jason could

get the basic measurements and pattern information he

needed.

|

|

Afterwards, with the main boom still in place, I did one

final preparatory step for the new lazy jacks,

approximating the positions for two legs to the boom and

cutting oversized lengths of line to run to the main

control lines above. I left these lines long and

awaited mast stepping and having the sail in place

before attempting to finalize the boom locations for the

legs. It looked like two legs would be enough, but

it'd be simple enough to split one (or both) into a pair

if needed. The main point of this exercise was to

locate and install the block at the end of the upper

control line, which location I determined by the whim of

my eye and the necessity to have the whole system be

retractable when not in use. |

|

Back on windlass duty a little later on, I started on

the foredeck, where I overbored all the mounting hole

locations for the windlass and chain stripper with large

bits to remove coring from these areas and prepare the

holes for epoxy filling. I also drilled the large

hole for the chain through the deck. |

|

Afterwards, I filled the holes with a thickened epoxy

mixture, and sealed the exposed core edges in the larger

hole. |

|

After lugging the windlass on deck the other day--being

all bronze, that thing is inordinately heavy--I'd left

it in place for a time. To my disappointment, I

later discovered some of the windlass oil running down

the deck, suggesting that the gasket material I'd

applied when I installed the motor hadn't "taken"

properly. This left me no alternative but to

remove the windlass back to the bench and reseal the

motor. Apparently, I'd not allowed the liquid

material the required few minutes of air-cure time

before assembling the parts before, so I made sure to do

so now. After assembly, I left the windlass tipped

on end so that the oil in the reservoir would stay clear

of the flange area to give the liquid gasket plenty of

time to cure and make itself right this time. |

|

At the helm, I chose a location for a remote switch for

the windlass, and cut an opening for the switch body.

During the cable run for the windlass, I'd led a

two-conductor cable (red and yellow) from the

chainlocker for this purpose (the other end would

connect to the appropriate terminals on the windlass

solenoid up in the chainlocker, which I'd install next).

While both wires of this cable were positive in

function, I chose to overlook the cable color problem,

but marked the switch and cable clearly as to the wires'

functions. The third terminal on the switch

was a ground wire, which I led in to the console and to

one of the negative distribution busses. |

|

With the switch wiring complete, I installed the panel

in the console, bundling and securing the wires as much

as possible but leaving enough excess to easily remove

the switch for servicing. |

|

I was still awaiting the main breaker panel for the

windlass, which incorporated a 150-amp breaker, so I

couldn't complete the positive cable runs till that

arrived. However, I could--and did--make up the

negative main cable end, securing it to the negative

distribution buss. It's the large black cable on

the lowest stud. |

|

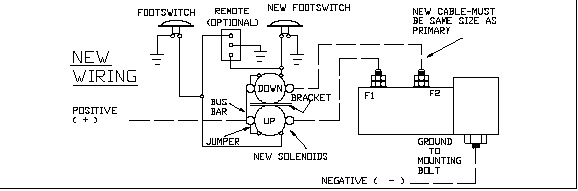

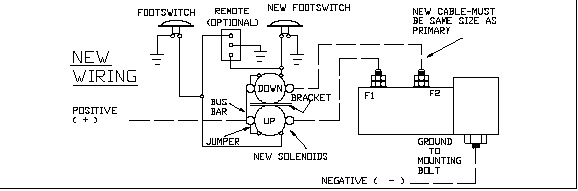

Moving my wiring operation to the chainlocker, I began

by choosing a mounting location for the solenoid unit.

Eventually, I decided the underside of the deck was best

for many reasons, chief among them ease of access and

protection from damage. I made sure to mount it

well clear of the bolt holes and backing plate for the

windlass installation (marked roughly in black marker).

Before mounting, I'd marked various terminals on the

solenoid (as determined by the wiring diagram) for ease

of reference during wiring and later. |

|

The main positive and negative cables were already led

into the space, along with the two-conductor wire

leading to that helm switch. In addition, I'd

pre-wired the two foot switches in the foredeck when I

installed them some time earlier. Now, I made up

the ends of these wires and connected them as required:

positive leads from the two foot switches and helm

switch to the up and down terminals on the solenoid,

respectively; positive main cable to one of the large

studs on the solenoid; and the negative leads from the

two foot switches, plus the main negative cable, which

for the moment I left dangling as these would eventually

be grounded to one of the windlass mounting bolts when

it was installed.

In addition, I also made up two shorter 1/0 cables that

would lead from the up and down sides of the solenoid

(at the forward [upper] side of the unit) to the studs

on the windlass motor on deck, but I left these hanging

in the space pending final installation a little later

on. |

|

This wrapped up everything I could do until [a] I

installed the windlass unit on deck (awaiting only new

bronze bolts and final hole and surface preparation) or

[b] I received the necessary breaker for the console end

of the system.

|

Total Time Today: 6.75 Hours |

<

Previous | Next > |

|

|