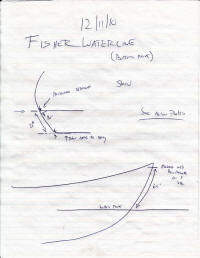

Project Log: Saturday, December

11, 2010

I was ready to begin work on the hull. Despite the

generally good condition of the existing hull

surface--it had been painted with Awl-Grip in 2002--I

knew from early on that I'd be repainting. I

preferred a different color scheme, and wasn't happy

with certain aspects of the existing paint job. I

wasn't about to go through this rebuilding process only

to settle on a so-so hull appearance.

My first step was to determine some reference points for

the existing waterline. (Note: when I say

"waterline", I mean the top edge of the bottom paint.)

Based on the general appearance of the existing

waterline and boottop, as well as some in-water photos

of the boat taken at an earlier time, I planned to

restrike a new line from scratch, but I wanted the basic

reference points duly recorded before I proceeded, for

whatever they were worth.

At the stern, I measured up to the waterline from a

straightedge held along the base of the skeg. The

existing waterline took a little dip right at the end,

where the molded shape of the stern made an abrupt

change in direction, and this resulted in the waterline

and boottop taking an awkward and unsightly jog

downward. So I compensated for this in my base

measurement. The measurement I recorded was 21",

as shown in the photos (the tape was held at 4" at the

starting point to allow it to lie flatter). |

|

At the stem, I hooked the tape into the bottom edge of

the bow roller assembly, and measured down the curve of

the stem to the waterline, recording 66". |

|

With these measurements and reference points filed away,

I could move on with the hull work and not worry about

the position of the existing waterline and boottop,

which would soon be sanded away.

One of the distinguishing features of Fishers is the

series of wooden strips that cover the outside of the

bulwarks. In order to paint the boat, I thought I

needed to remove these; plus, they were in fairly

decrepit condition, and it'd be easier to sand and

varnish them on the bench.

Each strip was held in place with screws, which were

hidden from view with bungs. To remove the strips,

I first center-pointed the bungs, then used a 1/2"

Forstner bit to drill away the bung, exposing the screw

head. Everyone always says to break the bungs out

with a chisel, but I vastly prefer this method. It

takes a modicum of care to ensure the bit remains

centered in the bung, and to avoid damaging the screw

head. |

|

Once the screw heads were exposed, I cleaned out the

slots and removed the screws, beginning at the bow and

working my way aft. Each of the three tiers of

teak comprised three lengths of wood, joined together

with half-lap joints where they met. So it was

surprisingly easy to remove all the wood from the

starboard side, and all nine pieces came off without

incident and appeared to be worthy of re-use.

I did discover that there were screws driven into the

top edge of the top board from within the caprail above,

so I had to go on deck and remove all such screws before

proceeding. |

|

The starboard side went so swimmingly that I moved

directly over to the port side, expecting to finish the

removal before lunch. Unfortunately, things were

different on the port side; a bit of explanation and

backstory is in order.

Something I've not yet discussed here is the fact that

the boat was clearly involved in some sort of collision

in the past, on the port bow. Even though I didn't

know what had happened, I'd noted a number of pieces of

evidence as I worked my way through the boat to this

point.

One of the things I noticed first was an area on the

port sidedeck, right at the forward side of the forward

freeing port, where there was clearly an area that had

been painted. This was obvious since the deck was

otherwise original gelcoat, but there was aged and

blistering paint in this area. |

|

A further sign of this past damage could be found inside

the forward cabin, in way of the round ports in the

hull; here, there was evidence of a patch. The

work appeared good, and this caused me no concern, but I

wondered what had happened. |

|

The final piece of the puzzle, as it were, came to light

as I tried to remove the bulwark strips on the port

side. I began, once again, at the bow, since the

half-lap joints were aligned with the forward piece over

the piece behind. As before, I removed the bungs

and screws with no trouble. However, these

boards--which, upon closer inspection and with the

benefit of new-found knowledge, were clearly newer than

the remainder--appeared to be bonded to the hull (and,

worse, to the half-lap joints) with some sort of

adhesive.

This made removal extremely difficult, particularly the

lower board, since there was little room to insert a

prying tool beneath the board. Eventually, I did

manage to pry the boards loose, but discovered--as

alluded to above--that the boards were also similarly

glued to the half-lap of the board behind, which was a

real problem.

The adhesive (or sealant) in question was black in color

and had been slathered all over the backs of the boards

on their bonding surfaces, though fortunately all of the

stuff hadn't contacted the hull. I wasn't sure

what the material was; it acted in many ways like

silicone, and it's possible I uttered a few choice words

about whoever had done this installation.

My solution to this, for the moment, was to remove the

screws from the next length of board, and then take down

both forward pieces at the same time, being extremely

careful not to stress the wood around the firmly-glued

half-lap.

However, despite my best efforts, I did slightly damage

the wood just forward of the half-laps on the lower and

middle tiers--but managed to avoid any true breakage.

But on the top board, which was also adhered to the

bottom of the caprail with whatever evil black compound

had been slathered everywhere, the bond was so

tight--particularly at the screw located just forward of

the joint--that shortly before the last bit of adhesive

released, I heard a sickening cracking sound, and the

forward board broke a couple inches forward of the

half-lap. This displeased me, and I might have

muttered some derogatory comments aimed at the previous

installer.

The remaining boards on the port side were clearly

original, and came off as easily as their counterparts

to starboard. Later, I scraped off the offending

sealant or whatever. It scraped off the hull

easily--more easily than I'd expect of silicone--but the

gobs of it on the back sides of the boards seemed

resistant and rubbery to the touch, like silicone.

I really was unsure what it was, but I didn't like it. |

|

What became all the more clear now was that

whatever had happened to the boat, clearly these wood

strips--just the forward third--had been replaced at

that time, along with the forward half of the wide teak

rubrail just beneath. (I now remembered the

previous owner telling me he'd replaced the rubrail,

though it was clear only the port forward section had

been done.)

In fact, the boards must have been replaced when the

boat was painted, as there was a clear paint line in the

recessed bulwark area that had been previously hidden

behind the boards; none of the original boards had been

removed for the paint in 2002, and these areas were

original green gelcoat. This led me to believe

that the reason the boat was painted in the first place

was probably to hide the repairs to the port bow, after

which the affected pieces of wood trim were replaced as

necessary. |

|

In any event, all the teak boards were off, and I'd have

to spend time later to see if I could de-bond the

half-laps on the port boards. But that'd be for

another time.

I really wanted (in an obligatory sense) to remove the

rubrails too, in order to clean them up, refinish the

back, mating surface, and to ensure that they were well

sealed to the hull at the fastener locations. Most

of the fasteners were easily accessible from inside the

bare hull, but the aftermost bolts still seemed

virtually impossible to reach, even with everything

removed from beneath the cockpit. I postponed any

decision on the rubrails for now.

I hated the thought of not doing an unsavory chore while

I had the most logical chance, but at the same time I

also hated the thought of removing and then reinstalling

these rubrails--all the more so because I figured

whatever fool had bonded the bulwark strips the way they

had probably would have used similar stuff on the new

forward port section of the rubrail, and I didn't want

to damage that either.

Moving on, I now got started on what I'd expected to be

the main focus of the day: sanding the hull to

prepare it for primer and paint. The existing

paint was in good-enough condition that I'd only need to

thoroughly sand the surface; there was no need to

attempt to remove all the old paint, as I often need to.

In addition, I knew the old paint--Awl-Grip--would be

compatible beneath the new paint.

To begin, I sanded everything I could reach from the

floor. Using a 6" finishing sander, I sanded first

with 80 grit paper, then followed with 120 grit.

In this way, I worked myself around the hull. |

|

Afterwards, I had enough time left in the day to begin

some of the staged work, beginning at the port transom

and starting to work forward. My small

rolling staging worked well throughout the day's

processes, since I'd still not managed to put together

any real staging for this job. |

|

Total Time Today: 6.25 hours

|

<

Previous |

Next > |

|

|