Project Log: Sunday, January 15, 2012

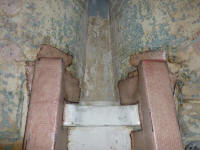

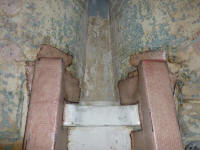

Now that the newly laminated engine bed extensions had

cured overnight, I water-washed as usual, then sanded

the surfaces as needed to remove any ridges left over

from yesterday's work, and also ensured that the top

edges and aft corners were smoothly contoured.

After cleaning up, I was ready to proceed. |

|

I prepared two layers of heavy biaxial material to

encapsulate each side and tie in the new material with

the existing foundations, trimming the fiberglass as

needed to fit properly over the new foundations. I

extended the material all the way to the base of the

drip pan in the center, and nearly to the hull on the

outboard sides, leaving room to keep the existing

limbers clear. The pieces were identical

(except reversed) for each side, so once I'd made one

pattern I could use it to cut the other three pieces as

needed.

Before continuing with the tabbing, I took care of a

couple small details. At the forward end of the

foundations there existed a small gap next to the

forward bulkhead. Thinking that this gap would be

a constant debris catcher if left alone, I mixed up some

filler and applied it to the gap, forming a smooth

transition between the engine beds and the bulkhead.

This was for purely cosmetic reasons. |

|

At the aft end, I started with a small piece of separate

tabbing, which I cut and darted to fit around the aft

end as needed to close off this area. Because the

foundations were solid fiberglass, there was no

particular need to ensure full encapsulation (as with

wood), and this small bit of tabbing was not intended to

provide much in the way of structural support, but for a

clean appearance and to avoid dark corners to catch

debris, I needed to close off the remaining gaps where

the aft end of the foundations died off into the hull.

I'd filled some of this gap with an epoxy fillet during

yesterday's lamination, but the gap was too large on the

inboard side, and filling the entire area solid seemed

wasteful. Instead, I let the tabbing run over the

gap and down to the hull, providing the first layer of

what would end u being a little fiberglass wall.

Finally, I precoated the foundations with plain resin.

This, along with the nicely rounded top edges, would

help the fiberglass overlay stick to these contours when

installed. |

|

After allowing the resin coat to tack up during lunch, I

returned to the shop and, one side at a time, wet out

the two layers of fabric on a table, then installed them

on the foundations, draping the material over the top of

the extensions and down the sides as need be.

There was no problem keeping the material well stuck to

the rounded top corners. |

|

To complete the fiberglass work on the foundations, I

installed small pieces of lightweight cloth over the

very ends, to ease the transition between the new

structural material and the forward bulkhead (with the

fillet I'd created earlier) and the short vertical aft

ends. I installed this light material for purely

cosmetic reasons. |

|

I turned to the helm mockup once more. Picking up

where I left off earlier, I continued various layout,

conception, cutting, and design-on-the-fly to slowly

ease my way towards the vision in my head, all subject

to constant change in the face of harsh reality.

My idea was to partially recess a reduced version of the

electronics pod to minimize its bulk while retaining

practicality. I had to operate within the confines

of the 5" deep space that existed beneath the horizontal

dash on the boat, between the dash and what would

eventually be the saloon overhead (as previously defined

by the plywood support cleat I'd installed on the

bulkhead). |

This cleat shows the vertical space

available

beneath the dash

|

An old photo from 6/21/11 showing the

open space beneath the dash

that I had to work with

|

Please bear with the numerous inelegancies of the

mockup. There was still work to do and changes to

make. The build process turned out to be highly

fluid, so the results were necessarily raw. At

this point, I was looking to prove to myself a concept,

rather than an accurate template for later use; once I

got to a point that I could deem successful, I'd likely

build an accurate mockup version based on the

experience.

The focal point of the helm had to be the large

navigation display. This needed to be front and

center, easily viewable, and easy to use without

obstruction. Next in the hierarchy of importance

was, of course, the helm and engine controls themselves.

From here, I felt most of the desired features could be

manipulated and relocated as need be.

Working towards this vague concept, while staying within

the bounds of reality, I made a cut in the bulkhead and

dashboard, then used the cutoff to create a new "floor"

for the recessed area. |

|

I couldn't begin to explain the various thoughts and

measurements and steps that led me forth, but over the

next couple hours my design continued to morph into

something that slowly gained potential. I made

various changes to my early cuts, and eventually managed

to piece together a very rudimentary form of the

concept, though already I was formulating ideas for

improvement and other changes. |

|

Design in three dimensions requires the ability to

change on the go. For the moment, it looked like

I'd managed to create a fine podium, but though I'd run

out of time for now, I looked forward to fine-tuning the

ideas into something even more workable. There

were a few constants in the layout that I'd have to work

with no matter what, but the exercise had moved me

closer to a final version. Among the manipulations

I had in mind was to more smoothly integrate the raised

portion of the box with the remainder, and to return the

angle of the lower dash--the engine control/instrument

panel--to the 20° I'd used in the original version. |

| |

Total Time Today: 6.25 hours

|

<

Previous |

Next > |

|

|