Project Log: Saturday, November 10, 2012

In the couple weeks since I milled the ceiling strips

for the forward cabin, I'd hoped to have a chance to

pre-finish them, but hadn't had time. So to begin,

I laid the strips out on some horses and applied a coat

of natural tung oil, my choice of finish for the strips

since it was easy to apply. I applied a coat to

all surfaces to seal the wood, and left the strips to

dry. I figured at best, I'd be able to work with

the strips in a day. |

|

Over the past several days I had had time to complete

the varnish work on the companionway trim and

companionway ladder. |

|

To install the companionway ladder, I first covered the

face of the access hatch with tape so I could make

reference marks, then installed the hatch in the boat

and, using two scraps of material the same thickness as

my finished cabin sole would be, aligned the new ladder

against the hatch to which it'd be attached, and traced

the outline on the tape for reference. |

|

Down on the bench, I realigned the ladder according to

my marks and, from the back side, drilled pilot holes

through the plywood and into the cherry ladder, then

secured it with screws after removing the tape. I

reinstalled the sound insulation on the back of the

panel, which I'd removed in order to secure the ladder.

Keeping the sole scraps in place, I reinstalled the

panel in the boat. The ladder worked great. |

|

At this point, I discovered to my pleasure that the

ceiling strips had dried much faster than I'd expected,

and were dry enough to handle. I'd apply most of

the finish once they were in place, and only had needed

the sealer coat on the back side first, so I decided to

continue with the installation. Later, once the

whole ceiling was installed, I'd apply several more

coats to achieve a finish similar to the satin varnish

elsewhere in the cabin.

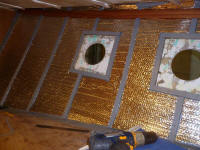

Installation was slow going thanks to the tight working

quarters and the need to custom-cut each piece.

Starting at the top, the first strip on each side was

the most difficult. I used two overlapping

sections of scrap plywood, cut to the same dimensions as

the ceiling strips, to determine the overall length and

angles at each end, and cut the first strip for each

side.

Allowing the board to fall naturally into position, I

found that the forward ends angled upwards more than the

curve of the deck would suggest, thanks to the compound

curvature of the hull and the increasing flare as I went

forward, but after attempting to keep the strip in line

with the angle I'd determined for my deadlight frames

(I'd expected the ceiling strips to be parallel to these

frames), I discovered a number of problems with that

approach, mainly that the strips ended up below the line

of the overhead panel frames in the middle section; I

planned for the overhead to hide the top seam of the

ceiling. If I'd continued in this way, I would

have had to make a custom piece for the top to

completely hide the hull and insulation, and this didn't

seem worth the effort.

So I decided to allow the strips to fall where they

wanted to, in the most natural way. I installed

the strips with bronze round-head screws, one at each

support location.

|

|

I'd decided to work on both sides at once to keep the

materials as consistent as possible, in case I ran out

of milled material before the end and had to use another

board. The boards I'd previously milled varied in

color, so I chose pieces entirely at random to avoid any

patterns. With the top boards installed, it was

easier to work on the next ones, as I had a natural

alignment point.

One board at a time, I worked down from the top till I

reached the deadlight cutouts, where I had to start

cutting little wedges out of the strip to fit around the

opening. (Later, there'd be trim to hide the raw

edges of the openings.) I measured and

marked the fourth board on the port side, but didn't

install it as I was running out of steam. But on

the starboard side, I completed the last long board, so

the next set of planks would be shorter and fit between

the deadlight openings. |

|

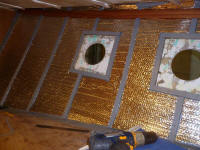

The bad angles looking into the space meant that

photographing the work was difficult. |

|

Total Time Today: 6.25 hours

(plus 2.25 hours spread over several preceding days) |

<

Previous |

Next > |

|

|