Project Log: Friday, March 14, 2014

In the head, I decided to install the large waste pump,

seeing no reason not to get it out of the way.

Installation was straightforward since I'd already laid

out and prepared all the holes required. I used

1/4" machine screws with fender washers on the outside,

since operation of this pump would stress the bulkhead

and the pump's fastenings. Access to the pump

through the nearby access opening was excellent.

|

|

Included with the kit was a rubber bellows and trim

piece, which I installed over the pump handle from

outside. |

|

To get a sense of the finished space, and also to

temporarily "store" the unit till final installation, I

dry-installed the plastic access hatch in the panel with

a couple screws. I chose the latch-down

orientation because I thought it would be the most

water-resistant, with the hinges facing up. To

hold the hatch open, later I'd add some means of

securing it to the bulkhead above. |

|

Other than seam caulk, paint, and final plumbing

installation, the head compartment was complete, and for

the moment I moved on to other tasks, starting with some

hardware installation on the foredeck.

To service the forward water tank, located beneath the

v-berth, I needed a tank fill nearby. Much

earlier, I'd purchased one that shared its appearance

with those back in the pilothouse, though for this one I

planned a separate (internal) tank vent rather than the

integral vents like those used back in the pilothouse.

To locate the fill, I started belowdecks, and drilled a

small pilot hole through the center of the old tank

fill's location, which I'd patched during early stages

of the project. Back on deck, I found that the

pilot hole wasn't quite where I wanted the fitting to be

centered, so I adjusted slightly as needed before

drilling the large hole required, centered in the V

shape of the nonskid pattern. The pilot hole

worked out well as one of the three fastener holes

required. |

|

Next, in the usual way, I marked and overbored the three

fastener locations, removing core from these areas, and

also removed the coring from around the large hole

before masking around the opening and the mounting

flange of the tank fill itself. |

|

To service the eventual saltwater washdown pump, I found

an interesting flush fitting for the purpose, which

incorporated a spring-loaded mechanism and a special

hose adapter. To use the fitting, and access

water, one simply pushed the adapter into the fitting,

compressing the spring and allowing water flow.

Removing the adapter would stop the flow. No taps

needed, and the fitting had a clean profile. |

|

I located the hole for this fitting just aft of the

water tank fill, and in line with it according to the

outboard edge of the nonskid pattern. I prepared

the mounting hole the same way, removing core from the

areas directly surrounding the opening and the

fasteners. |

|

One of the reasons I selected an older Ideal Windlass

for my first personal foray into the world of windlasses

was stuff like this: these hefty bronze housings

that protected the wiring for the foot switches.

Things like this exude good design and engender high

confidence. These would mount to the switches from

belowdecks, allowing future access if needed.

Because their bolt patterns and mounting flanges were

the same as the switch plates themselves, I used these

for layout purposes since they were more convenient to

work with than the switches and their mounting plates

themselves. |

|

Belowdecks, I made a measurement from the water tank

fill to the chain locker bulkhead, so I could transfer

the bulkhead's position to the deck. I wanted the

foot switches to come through in the chain locker, where

the wiring would be hidden and protected. Allowing

plenty of extra room, I determined 10" to the bulkhead,

and made a mark on deck. |

|

Striking a perpendicular line to the centerline of the

boat, approximated off the raised center portion of the

foredeck, I determined the positions for the two foot

switches. Once happy with the position, I marked

the centers of the holes with a pencil. |

|

With a hole saw, I cut out the holes as needed, then

prepared them as with the other openings, removing core

and preparing the fastener locations before outlining

the mounting flanges with tape. |

|

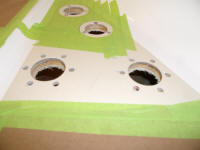

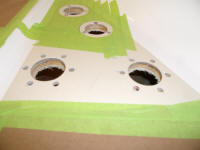

With all the openings prepared, I masked over the holes

from belowdecks (only the large holes went all the way

through the decks; the drilled openings at the fastener

locations only went as far as the inner skin), and

installed a thickened epoxy mixture in the fastener

holes and around the perimeters of the through-deck

holes, protecting the core beyond from water intrusion. |

|

I thought it would make life easier if I pre-wired the

foot switches on the bench before installation.

While there'd be decent access inside the boat, dealing

with small terminal screws overhead in an awkward space

was something best avoided whenever possible. So I

installed wire pairs to each of the two switches.

My first go-round, with sheathed 2-conductor cable,

proved that it was too hard to snake the flat cable

through the bronze nut at the bottom of the housing, so

I switched to individual wires, leaving enough slack for

eventual routing to the windlass solenoid that I'd later

mount nearby.

The first photo shows how the housings and switches

eventually work together, with the deck in between, and

the second photos shows all the components ready for

final installation. |

|

We wanted some sort of sturdy, permanent boarding

ladder, as the overall design of the boat, with her high

bulwarks and coamings, made ingress and egress to a

dinghy more challenging than on some boats. Over

the years, I'd determined (probably) that the best bet

was going to be a permanent ladder mounted to the

transom, but how exactly to configure this--and then

have it built--required a mockup. I thought maybe

I could build a "ladder" out of plastic pipe to serve as

a realistic template for the final thing.

To start, I made some basic measurements to determine a

ladder width and tread spacing that worked, both with

the shape of the canoe stern and with the eventual

landing points on the caprail. It looked like

about 16" between vertical rail centers would be good,

with a 12" tread spacing, so I prepared various pieces

of pipe to the appropriate dimensions, using T

connectors to put them all together into a 4' long

starting section. |

|

This was the easy part. The hard part would be

determining the design of the top section, and how to

mock it up (if it was even possible), and how and where

to land hull supports for the lower section of the

ladder. I played around with my little ladder

section for a while, attempting to visualize the next

steps that I'd continue soon, but for now the day was

done. |

| |

Total Time Today: 6 hours

|

<

Previous | Next > |

|

|