Project Log: Saturday, January 15, 2011

Before I could cut and fit the second section of cabin

sole substrate, I had to make some decisions about the

first section, and determine how I planned to lay out

the bilge access hatches. In order to do this, I

first needed to work on some preliminary--and

basic--layout questions.

I didn't plan any major changes to the layout of the

main cabin from the original configuration. I'd

finesse the layout a bit to better suit our way of

thinking, but in general there would still be a

longitudinal galley to starboard, and a dinette to port.

(What there wouldn't be was the unnecessary and

space-wasting quarterberth on the starboard side in that

space aft of the galley; this space would be better

utilized in the engine room and galley, respectively.)

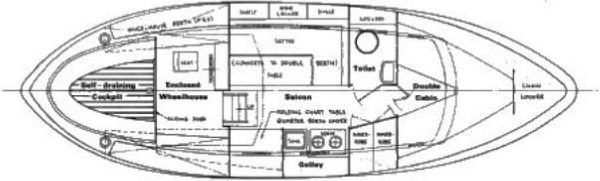

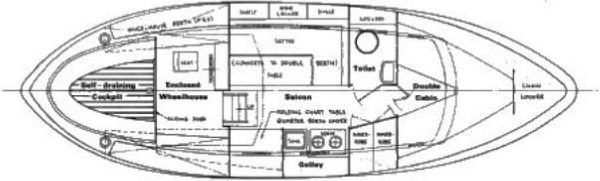

This fuzzy drawing from somewhere online shows the

basics of the original layout: |

|

The details of the new configuration weren't that

important yet, but what was important was for me to know

roughly where the dinette cabinets would land on the

sole, so I could plan hatches and plywood seams around

that information. I already knew essentially where

the galley cabinets would land, and because of their

position well to starboard these didn't factor into the

preliminary planning. My rough planning at this

stage allowed plenty of leeway for various manipulations

to the final dinette shape and layout, details of which

would make themselves clear soon enough.

When I initially demolished the original dinette

structure, I'd made some reference marks on the adjacent

bulkheads. These marks now allowed me to sketch

out the rough footprint (at least as originally

designed) of the cabinets on the new plywood sole; I

also measured for and marked the position of the

longitudinal support containing the two table leg bases,

which, whether I planned to re-use this support system

or not, factored into the various planning. I also

market the position of the support beams on top of the

plywood. |

|

What I accomplished with this hour's work was a

guideline for how and where to lay out the bilge

hatches, and also helped me make the decision to leave

the plywood seam right where it was, which would make

the second section quite small and easy to work with.

To this end, after ensuring the large section of plywood

was properly positioned, I made reference marks on the

tops of the support beams, and also at the forward and

after ends of the sheet where the marks would be easy to

see during later steps. Then, I removed the

large sheet back down to the bench, and prepared a

smaller blank from which I sized, scribed, and cut to

fit the second section required to make up the cabin

sole substrate. |

|

With the large piece of sole on my bench, I laid out

four access hatches for the bilge: three along the

sole's length a bit to starboard of the centerline, and

a fourth in the port corner in an area that would

eventually be located within the dinette seat cabinetry.

I sized the openings so they fell appropriately between

the support beams and so they were large enough to

provide the level of access I wanted to the space.

I didn't install a hatch at the aftermost end, as this

was where a ladder from the pilothouse would eventually

land, and from the aft hatch I could see and reach the

final portion of bilge anyway.

Once I had the hatches cut, I hefted the now

somewhat-lighter sheet back into the boat for a final

test fit. |

|

While the sole was back in place, I made additional

measurements and reference marks to fine-tune the

location of the table support receptacles, now buried

beneath the sole. I was unsure whether I'd use

these for my new table, or whether I'd install some

other sort of support, but I needed to be sure I

could accurately drill holes in the cabin sole to expose

the supports if I decided to use them.

I brought both pieces back down to the bench, and got to

work cutting and installing support cleats for the bilge

hatches, gluing and screwing them into position beneath

the openings. I chamfered the edges of the cleats

so there'd be no sharp corners or splinters. |

|

With the basic substrate construction complete, I coated

the bottom side and edges of the plywood with epoxy

resin to seal the wood. |

|

| |

Total Time Today: 6 hours

|

<

Previous | Next > |

|

|